ARTEC “AS” Series parallel shaft gearboxes are designed and manufactured in accordance with the latest technical standards. (AGMA, API and other standards or special designs upon request) As a result, ARTEC is able to offer highly efficient and reliable turbo gearboxes for a multitude of applications.

Get a Rapid Same Day Quote!*

Used in many applications

- Oil and Gas

- Power Generation

- Petrochemical Industry

- Energy recovery

- Testbeds

Freestanding parallel shaft gearbox designs

- “AS” Series type with steel casing for an extremely rigid construction

- Separate inspection covers for easy inspection and service access

- Gear ratio for all types: (Single-stage 1<10)

- Single or double helical gearing is calculated according to API and AGMA standards.

- Hydrodynamic cylindrical sleeve bearings or tilting pad bearings.

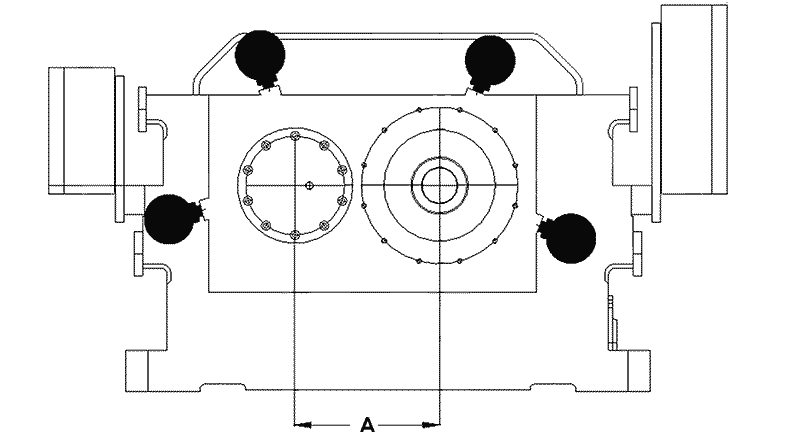

Top View

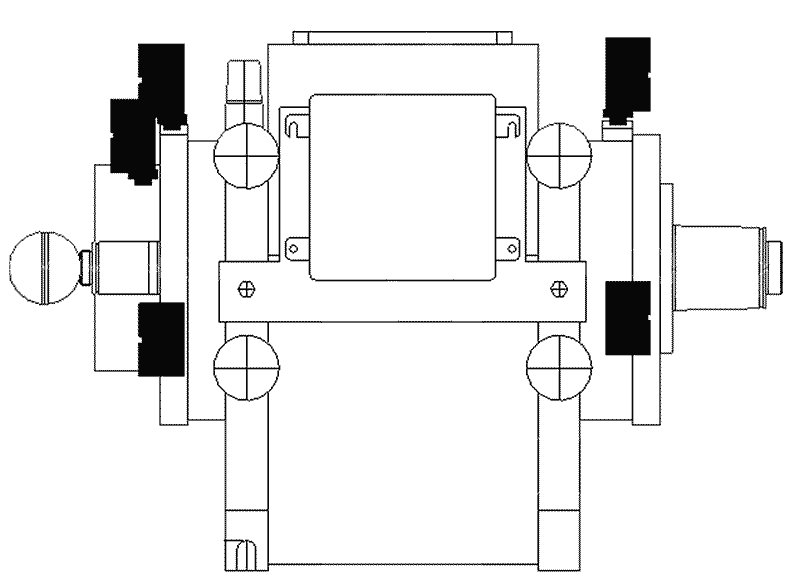

Bottom View

AS-Series Parallel Shaft Gearbox Design Details

Gear Rotor Toothing Modifications

Gears and pinions under load exhibit elastic deflections and the temperature across the teeth are asymmetric. Deformations and thermal expansion negatively impact tooth engagement. The tooth flanks are therefore modified during grinding to optimize load distribution at all loads and speeds. Compensation for torsion, bending, and thermal effects is absolutely vital for high-speed applications.

Journal Bearings

Pressure-lubricated two, three or four-lobe bearings provide excellent load capacity and journal stability. Gears that operate at higher velocities are equipped with direct lubricated tilting pad bearings. Bearings are designed to minimize losses while providing excellent stability at high circumferential speeds.

Thrust Bearings

The integrated tapered land is Standard tilting pad thrust bearings with direct lubrication can be provided if it is technically required.

Instrumentation

Standard instrumentation includes:

- RTD’s or Thermocouples on each radial bearing (2 each)

- RTD’s or Thermocouples on each thrust bearing, loaded and unloaded side (active/inactive side)

- Provisions for mounting two shaft-vibrations probes (90 apart) on each bearing (input/output side)

- A provision on the casing for mounting two accelerometer

- Other provisions according to customer requirements

- Keyphaser if requested

The “AS” Series gearbox

The rotors can be offset horizontally or vertically and are housed in ridged welded construction in two halves with an easy access inspection cover and for easy maintenance. The gears are typically carburized, hardened and ground, single helical or double helical. Reduction of noise and vibrations is key. ARTEC’s design incorporates toothing lead modification accounting for bending, torsional and thermal deflection - thus ensuring perfect tooth contact pattern in any load situation. The bearings ensure a high rotor dynamic stability with the least possible oil consumption and losses.

Key Features:

- Optimum center distance and optimum tooth width

- Toothing is ground in a longitudinal direction and in the direction of the profile to compensate for pre-calculated distortion that can occur in operation: Resulting in optimum tooth contact pattern under full load

- Bearings are designed to create a stable dynamic environment.

- Welded steel casing- extremely rigid design

- 4-point support casing for ease of alignment

- Adjustable radial bearing for perfect tooth contact pattern

- Single-helical or double-helical toothing

Monitoring equipment

A full range of monitoring equipment is available to complement the gearboxes. Items include integrated resistance thermometer sensors. Conforming to the requirements of API 670 or other standards, radial, and axial vibration sensors can be installed at all bearings.

*Same day quote available in most cases depending on the time of receipt and during normal business hours.