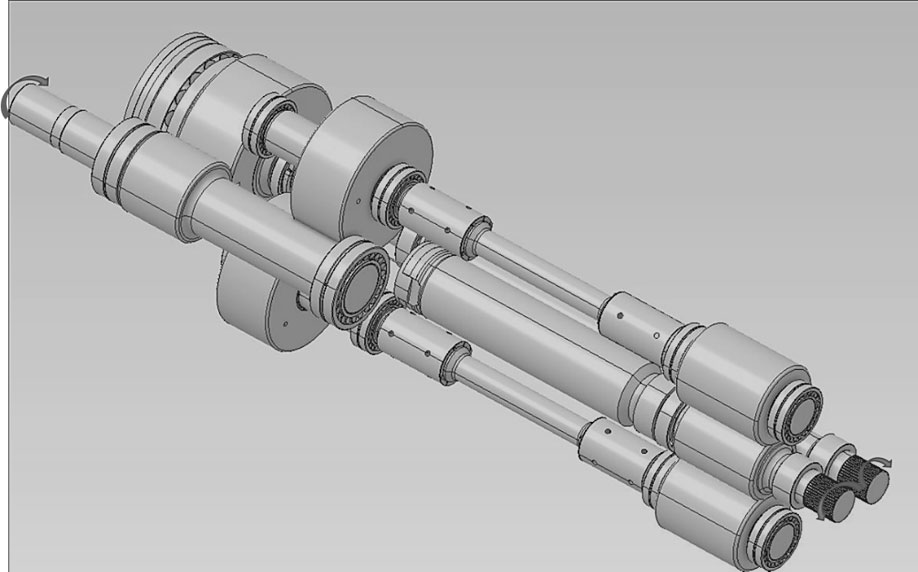

Special twin-screw extruders (synchronous) must be able to absorb the very high torques and axial forces set up by the extrusion process, Artec has developed an extruder gear unit with a double power-splitting system and special high axial load thrust bearings.

ARTEC’s robust line of twin-shaft extruder drives has been built for Super High Density/Torque applications for food processing industries. These NEW transmission drives are available to produce the highest working reliability for a given application.

Technical Parameters:

| Model / Item |

Main Motor |

Reducer Ratio |

Rated Output Speed |

Torque |

Torque Factor |

Axial Load |

| AEX192CR |

373 Kw |

105rpm |

17rpm |

204 kNm |

28.8 Nm/cm3 |

6000 kNm |

| AEX (range 130-200mm |

As requested* |

--- |

--- |

Up to 220 kNm |

--- |

--- |

*We can offer customer-made solutions of up to 220 kNm!

**Torque factor = torque divided by the cube of the center distance between the screws

ARTEC’s AEX Counter and Co-Rotating gearboxes

- transmit power from the motor to the extruder screws

- reduce the motor speed to the desired screw rpm

- maintains the angular timing of the screws

- takes the thrust load from the screw set

- Compact integrated design with high performance through the use of high-strength steel

- Optimal smoothness and quietness by ground helical gears and optimized tooth geometry

- High efficiency due to a minimum of rotating parts

- Superior reliability

The AEX drives are built within an extruder screw axle base range from 130 mm to 200 mm. The appropriate torques and rotating speeds are available depending on the application requirements.

Gear teeth are case hardened and ground, properly designed with gear tooth forms for handling deflections in bending and torsional loads. ARTEC’s long-standing background experience in the precision high-speed high industrial gear drives industry allowed us to ensure our NEW product is designed and manufactured to meet the most stringent requirements for upmost continuous performance.

The AEX gear system is separated into two distinct parts—the reduction input section and the distribution output section;

- The reduction section of the system is designed with a conventional helical gearbox. It is adapted to the motor speed with a single- or two-stage reduction unit integrally mounted from Bonfiglioli’s standard reducer program. This section reduces the motor input speed (1,800 rpm, for example) to the distribution section, which may be anywhere from 30 to 350 rpm.

- The distribution gear section takes a single-shaft input from the reduction gear and transmits it to two (2) parallel output shafts subsequently further reducing the system to the desired screw output speed. The power split of the torque 50% and 25%/25% occurs within the input pinion. The output torque is recombined and distributed equally 50%/50% to the two extruder output shafts by combining the loads with the telescoping articulated pinion shafts.

The AEX distribution unit is designed to accept the extreme axial force loads from the extruder’s screws by means of High Load Axial Tandem bearings and Self-Aligning Roller Thrust bearings. The tandem bearing system can consist of multiple thrust bearings layered (up to 8) one behind the other.

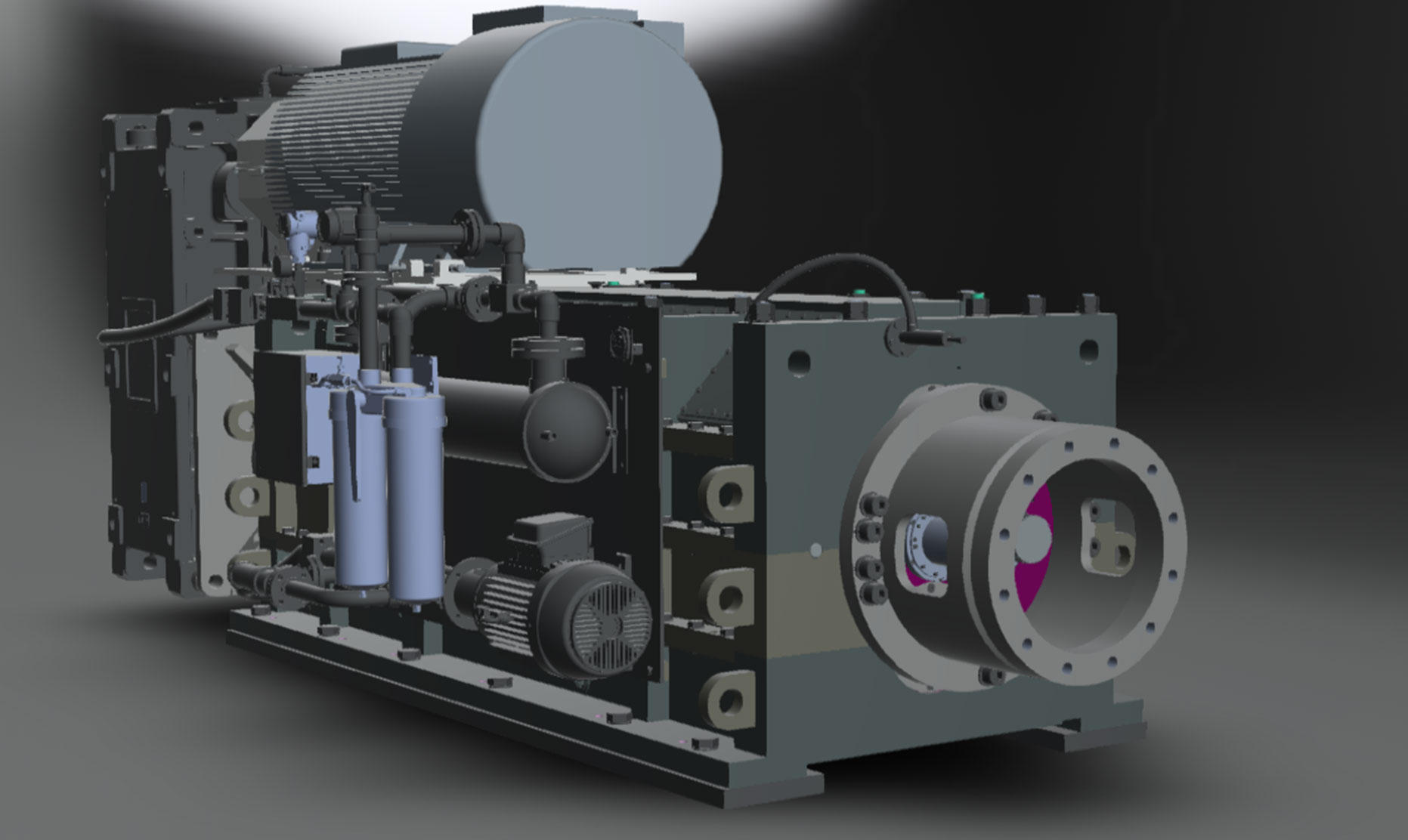

This gear unit’s housing is made of thick-walled fabricated steel with strongly ribbed interior and exterior elements. This robust design safely contains all the working gear train forces and fully accepts the extreme axial loads from the extruder forces.

The main VSD drive motor is top-mounted to the gearbox drive, it is integrally aligned to the reduction section of the system and is coupled with a mechanical over-torque coupling and automatically uncouples/disengages the motor if the torque exceeds a preset level.

The unit is equipped with self-contained lubrication oil systems which are a fully integrated with a combined splash and pressure system. An electrical oil pump ensures that all gears and bearings are sufficiently lubricated. The gearbox housings are utilized as the oil reservoir.

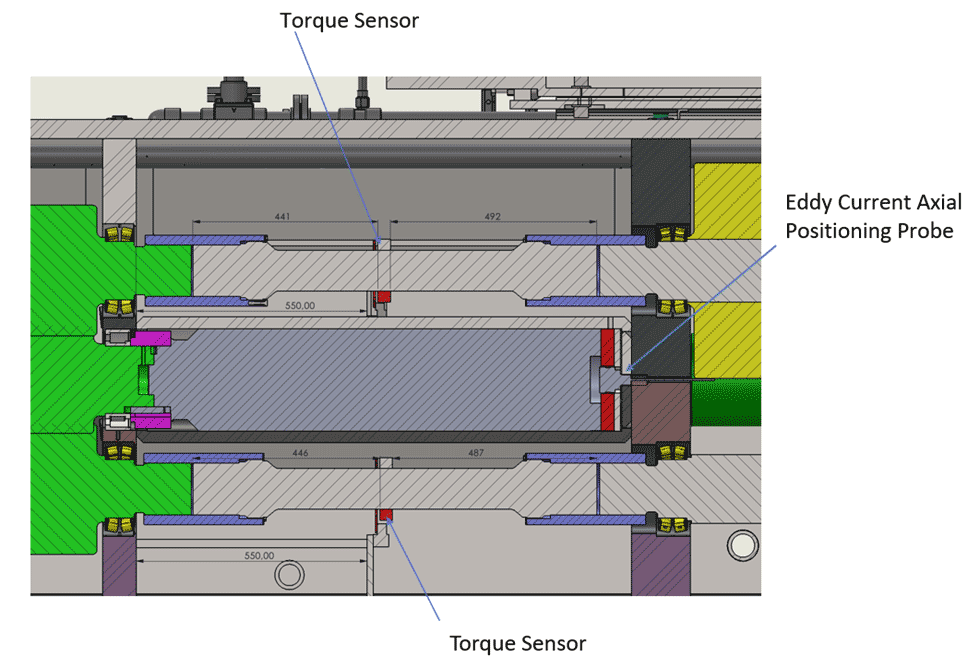

Condition Monitoring Systems

- A built-in torque meter system senses and analyzes the extrusion process torsional load and torsional vibrations.

- The 2 output shafts are individually known as the through shaft and tandem output shaft, are supplied with the following monitoring devices;

- The through shaft is equipped with an axial load cell measuring real-time axial forces of the extruder screws.

- The tandem shaft is equipped with an eddy current axial positioning probe to monitor the axial tandem bearing position and wear.

- The AEX casing is equipped with 2 externally mounted accelerometers to detect and observe bearing and tooth mesh frequencies for real-time condition monitoring.

- The AEX oil system is equipped with an oil debris Sensor System. The MetalSCAN 3500 Series oil debris sensor monitors metal particles generated from the internal rotating elements due to bearing and gear wear. The oil debris monitoring system enables early and simple assessment of how much time you have to schedule maintenance to prevent potential equipment failure.

- Temperature and pressure monitoring of the lube system are respectively controlled by the cooler automated temperature control value and pressure regulating flow system.

- A oil filter monitoring system; measures high differential pressure across the filter elements indicating when filters should be inspected and replaced.

The control of all ARTEC’s AEX extruder drive parts, as well as the test run of each gear unit, ensures a continuous high-quality standard.

ARTEC has developed this optimal solution with industry leaders where power is to be efficiently and safely transmitted.